State-of-the-Art Machinery

Cutting-Edge Solutions for Every Industrial Need

Sheet Metal Stamping & Assembly

Division

Precision-Engineered Components for Consistent Performance and Durability

Our Sheet Metal Stamping & Assembly Division is equipped with advanced

presses, high-precision dies, and automated assembly setups to deliver

consistent, dimensionally accurate, and high-quality components. Each

part undergoes rigorous inspection to ensure it meets the most demanding

industrial and automotive standards.

Precision Laser Cutting & Bending Solutions

High-Speed, Accurate, and Versatile Metal Processing

Equipped with advanced fiber laser cutting and CNC bending technology, we deliver precise, clean, and efficient metal fabrication for a wide range of materials. Our setup ensures faster turnaround, superior edge quality, and high accuracy across complex designs — ideal for automotive, industrial, and custom fabrication applications.

Advanced Fabrication Facilities

Engineered for Strength, Precision & Durability

Our fabrication unit is equipped with modern welding stations, cutting tools, and assembly setups to handle diverse fabrication requirements with accuracy and efficiency. From structural frames to custom assemblies, every component is built to meet stringent industrial standards, ensuring reliability, durability, and superior finish.

Modern Machining Facility

Precision CNC & VMC Solutions for Complex Components

Our machining facility houses state-of-the-art CNC and VMC machines designed for high-precision component manufacturing. With advanced tooling, automated operations, and skilled operators, we deliver superior dimensional accuracy and surface finish across all machining projects — from prototypes to large-scale production runs.

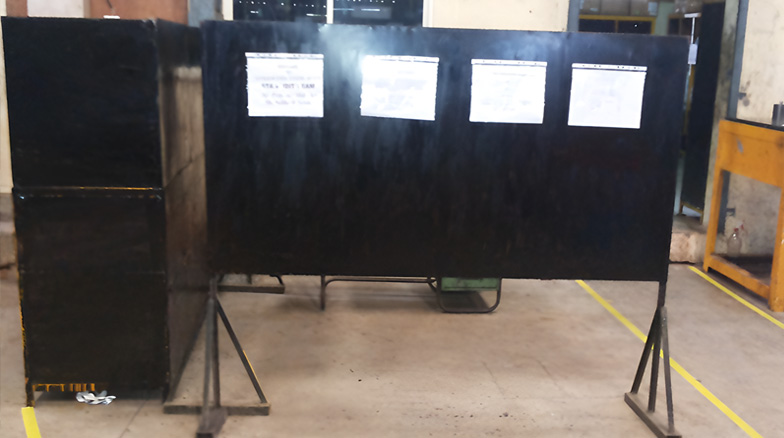

Quality Inspection & Testing Facility

Ensuring Accuracy, Reliability, and Excellence in Every Component

Our fabrication unit is equipped with modern welding stations, cutting tools, and assembly setups to handle diverse fabrication requirements with accuracy and efficiency. From structural frames to custom assemblies, every component is built to meet stringent industrial standards, ensuring reliability, durability, and superior finish.

Office & Administrative Infrastructure

Our Well-Organized Spaces for Efficient Operations

Excellence in Every Detail

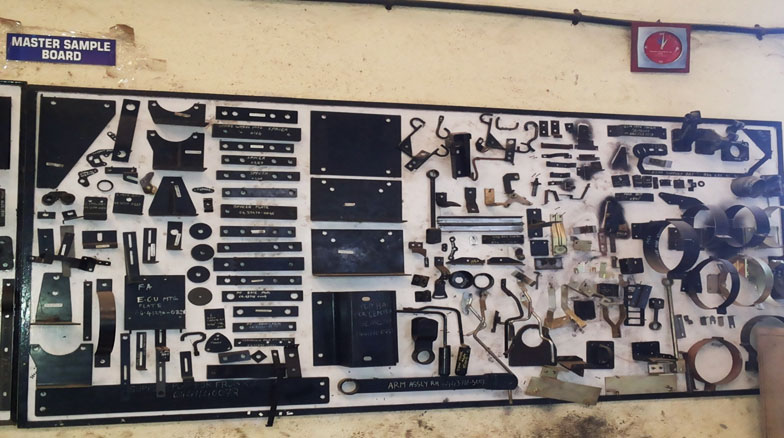

Master Sample Board

Meeting cum Display Area

A Collaborative Space for Innovation